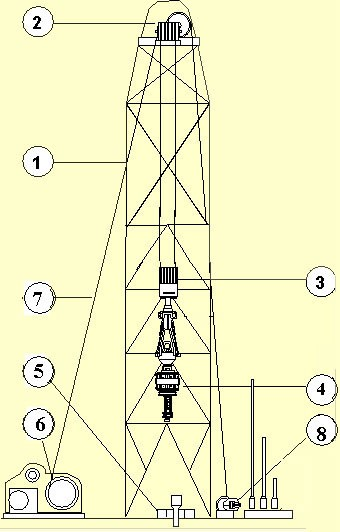

DRILLING LOADS

- Forces on the Derrick

Derricks are subjected :

- Weight of the derrick itself

- Wind load

- Stress induced by Floating hull motion

(for floating vessels)

- Horizontal component load of the drill string when racked back

- Hoisting load

The first 3 forces are considered in the structural design of the derrick.

- Calculation of Drilling Loads at Crown Block

Cases

Case 1: Suspended load

The load on the support is equal to the weight being hung.

Case 2a : Static Load

Drilling load is at rest, hoisted by the Drawworks over a single sheave on the Crown Block

The load on the drawworks is equal to the weight being hung from the crown sheave.

The crown supports both the drilling load and drawworks tension, so the force supported is double the weight being hung.

Case 2b : Dynamic Load

Drilling load is in motion, hoisted by the Drawworks over the single sheave on the Crown Block

The load on the drawworks is equal to the weight being hung from

crown sheave PLUS frictions.

The crown block supports both the drilling load and the drawworks tension PLUS frictions, so the force supported in more than the weight being hung.

Case 3: Drilling load is in motion

Drilling load is in motion, hoisted by the Drawworks through a series of sheaves on the Crown and Travelling Blocks

The load supported by the Crown Block is the sum of the load supported by each of the lines.

In this example with 3 lines, the load supported by Crown block is

1500 kg

The load supported by the Drawworks is the drilling load divided by the number of lines on the traveling block.

In this example the force required by the drawworks to hoist a weight of 1000 kg is reduced by by using a travelling block with one sheave.

The series of sheaves in Crown-Travelling Blocks system reduces the load necessary to hoist a weight.